An Expanded Residence Stress Distribution Study in a Twin-Screw Extruder: The Effect of Stress Bead Strength¶

Graeme Fukuda, Roba Adnew, Harry Brown II, Jesse Kim, and David I. Bigio Mechanical Engineering,

University of Maryland, College Park, MDAbstract

The ability to measure Residence Stress

Distribution (RSD) in real time provides a greater

understanding of the extrusion process. A method has been

developed to characterize stress history within a 28-mm

co-rotating twin-screw extruder (CoTSE) through the use

of stress beads that break at critical stresses. Three

different strength stress beads were used to provide an

expanded and robust methodology. A Design of

Experiment (DOE) approach was used to present the bead

breakup results.

Introduction

Extrusion has been a widely researched technique

used for mixing in many different fields. Studies have been

conducted in the pharmaceutical, food, and rubber

industries along with many others [1]. In addition, food

packaging has been an increased area of interest due to

improved properties for barriers protecting food from

oxygen, carbon dioxide, and water vapor [2]. Furthermore,

the advancement of processing polymer composites with

carbon based microfibers and nanotubes has gained

traction. Addition of these fillers can enhance mechanical,

thermal, and electrical properties [3].

Mixing is a critical component to the

characterization of extruded material. Screw configuration

is one such element that alters mixing within an extruder.

Many extrusion processes utilize a mixing section which

contains blades, paddles, or pins [1]. The two mixing

sections studied for this research were narrow and wide

kneading blocks (KB). Narrow KB induce low magnitudes

of shear stress but generate high strain this allows for better

distributive mixing. On the other hand, wide KB focus on

creating high magnitudes of shear stress, which is best

suited for dispersive mixing. Distributive mixing helps

create a uniform spread of particles within the extruded

final product. While dispersive mixing allows for the

capability of breaking agglomerates into smaller particles

[4].

The degree of mixing achieved in a twin-screw

extruder is one of the most important factors that affect the

properties of the final product [5]. Erwin demonstrated that

the use of a mixing section reorients the interfaces of the

fluid for greater area growth and thus better mixing [6]. In

order to successfully determine the degree of mixing that

occurs within the extrusion process, accurate modeling of the induced stress for a given mixing section and operating

condition is necessary.

Past studies have developed RSD measurement

techniques but nothing in real time. Wetzel et al used a

method of a single ultrasonic probe and a tracer to identify

the time the material spends in the extruder, which can

determine the RSD [7]. Curry et al used glass spheres to

measure the stress history. However, the method was

discontinuous because it required burning the polymer off

and manually counting the number of broken glass spheres

[8].

Recent studies using stress sensitive polymer

beads have been used to measure the stress history in real

time [9]. These studies were expanded upon to include

multiple stress beads that varied in strength in order to

observe the accuracy of the methodology. The study

produced similar results to research done with one strength

stress bead thus validating the method of experimentation

[10].

To further expand the analysis of the stress bead

approach this study was conducted using three different

strength stress beads. The DOE approach depicted the

percentage of stress bead breakup along a range of screw

speed (N) and specific throughput (Q/N). The DOE

technique also enabled a statistical analysis to determine

significant processing parameters and generate predictive

equations for percent breakup. The following paper

presents the results of the three stress beads.

Materials

High-density polyethylene (HDPE) Alathon

H6018 in pellet form from Equistar Chemicals was the

base polymer for this experiment. HDPE has a density of

0.960 g/cc and a melt index of 18.0 g/10 min. The stress

beads used were CAlibrated MicroEncapsulated Sensor

(CAMES) beads provided by Mach 1 INC. in King of

Prussia, PA. The CAMES beads measured the stress

during extrusion by breaking at specific critical stress

levels and releasing their encapsulated ink into the polymer

melt. The critical stress level of the beads depends on the

diameter and wall thickness of the bead. The three critical

stresses of the beads used were 92 kPa, 119 kPa, and 158

kPa. The 92 kPa and 158 kPa beads were blue and the 119

kPa beads were red.

For the blue stress beads the same dye that is

encapsulated in them, Automate Blue 8A, was used to stain

the polymer melt as a reference shot. For the red beads, the

dye used was Red B Disazo. The reference shots were

prepared by dissolving super high impact polystyrene

(HIPS) 935E pellets in a heated solvent. The reference dye

shots represented the paths taken if 100% of the stress

beads were broken. This 100% breakup can also be

visualized as Residence Time Distribution (RTD) because

it accounts for all the paths taken by all the different fluid

elements.

Equipment

The experiment was performed on a Coperion

ZDSK-28-co-rotating, fully intermeshing twin-screw

extruder. The screw diameter was 28-mm and the length

to diameter ratio (L/D) was 32. Also, it should be noted

that the extruder is a three-lobe machine. The extruder set

up has a feed port and one vent port before the mixing

section where the stress beads and the reference ink shots

were dropped.

Two different screw geometries were

investigated. Following a melting and conveying region

that were the same, the first mixing section was comprised

of four forward conveying right-handed narrow kneading

blocks 6.0 cm of total length, followed by a reverse

conveying element of 3.0 cm. This geometry ensured that

the mixing section would be filled for all operating

conditions. For the second screw geometry, three of the

narrow kneading blocks were removed and replaced with

one right-handed wide KB of 4.5 cm long. The reverse

element was kept as the backup element for both

configurations.

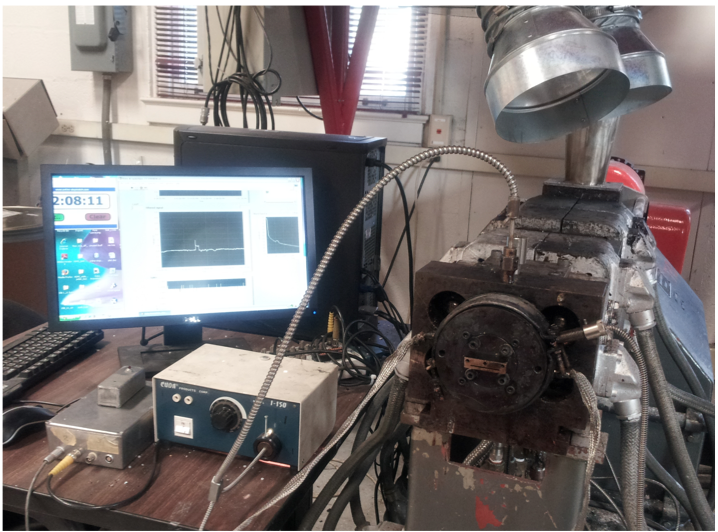

Figure 1. 28-mm Coperion Co-Rotating TSE and data acquisition setup

A reflective optical probe was placed above the end of

the mixing section where the screws are filled. The probe

consisted of a bifurcated optical fiber bundle enclosed in a

stainless steel shell contained in a larger stainless steel shell with a sapphire window. The probe was inserted into

a barrel through a standard Dynisco pressure transducer

port. The probe uses a split fiber optic bundle, where white

light is transferred from one bundle and enters the

extrusion melt. The light is then scattered by the stained

melt and enters back through the other fiber bundle. The

light recorded is converted to a voltage signal using a

photo diode and a signal amplifier.

Experiment

For this experiment, operating conditions were

chosen in accordance to machine specifications, in order to

obtain a wide range of data. The five barrels of the extruder

were set at 200°C and the die zone was set at 195°C for all

experimental runs. Operating conditions were varied by

specific throughput and screw speed.

Data was collected through the optical probe, and

due to the transparent nature of HDPE melt, TiO

2 was

mixed into HDPE to provide a white background so the

optical probe could take proper measurements. Since such

small amounts of dye were mixed with the HDPE melt the

concentration of the dye and polystyrene had a negligible

effect on the viscosity of the HDPE melt. Impulses of

stress beads and reference shots were injected in the melt

once a baseline was established in the data acquisition

program. Once the stained melt was completely extruded,

and the baseline had returned to its original position the

data acquisition program was reset for the next

experimental run. In total, nine operating conditions were

tested for each screw configuration, with an average of two

reference shots and two stress bead shots per condition.

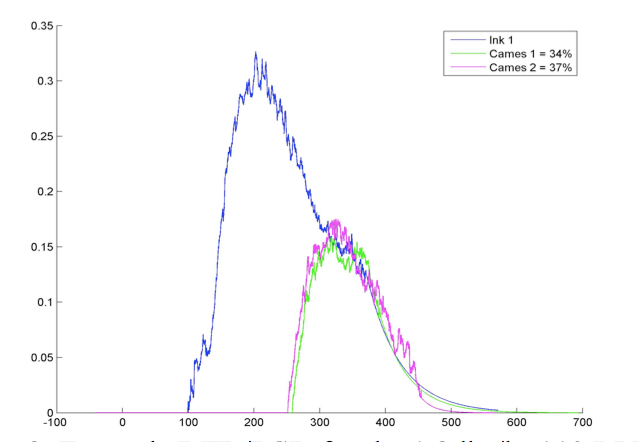

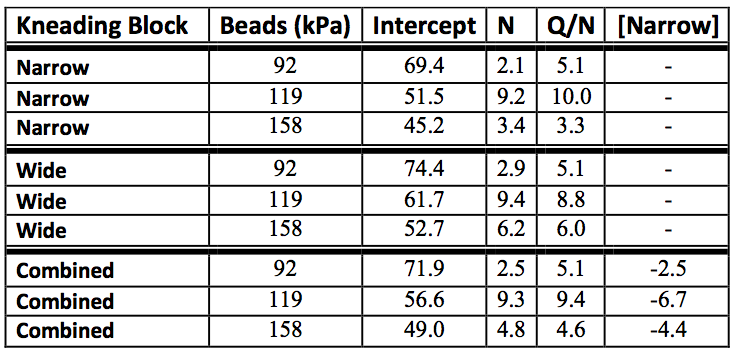

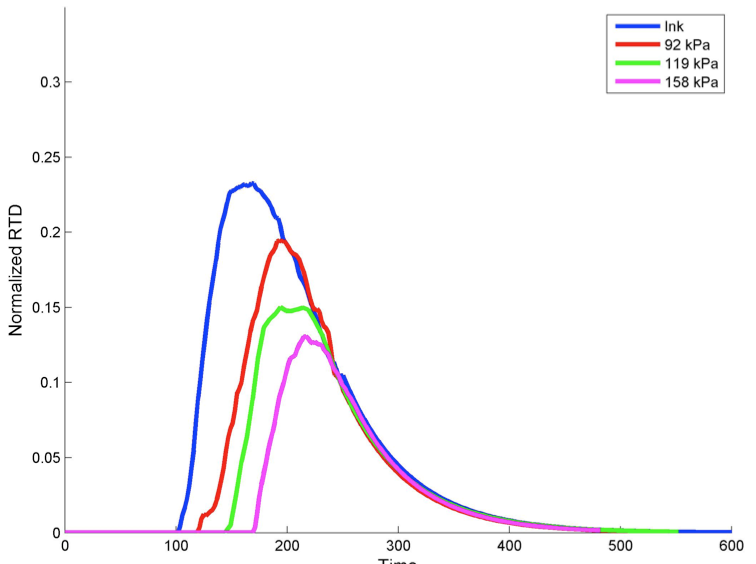

Figure 2 below is an example of the RTD and RSD curves

after analysis. The blue curve represents the reference shot

and the magenta and green curves depict the stress bead

shots.

Figure 2. Example RTD/RSD for the 1.8 lbs/hr 110 RPM experimental condition

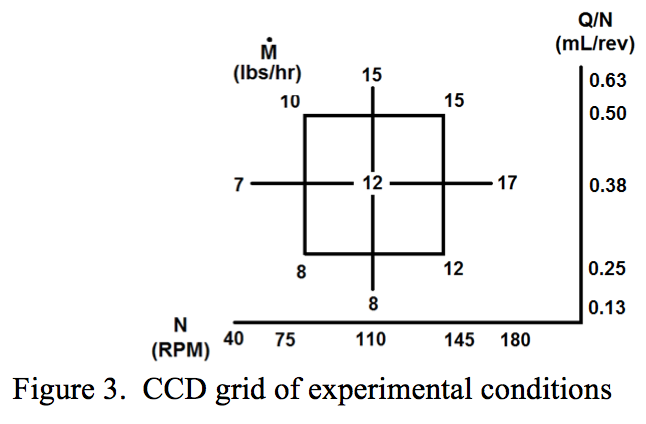

Experimental Grid

The central composite design (CCD) grid was

chosen for its statistical advantages and visual

representation of the data. Additionally, the CCD grid

clearly displays the relationship between percent breakup

and operating conditions. The vertical axis represents the Q/N in units of mL/rev. The horizontal axis represents N

which is in units of RPM. The values on the grid in Figure

3 represent the mass flow rates in lbs/hr for all nine

experimental conditions. The axes were chosen because

RTDs scale with N and Q/N.

Figure 3. CCD grid of experimental conditions

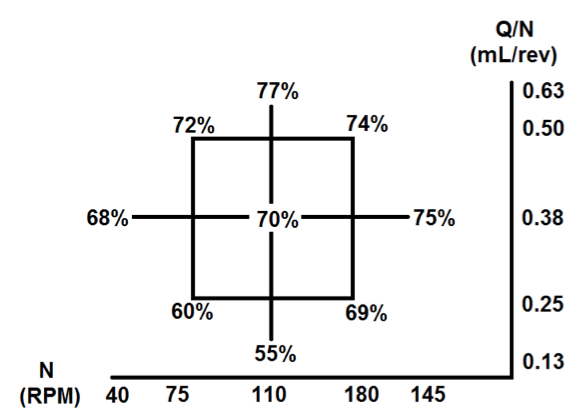

Experimental Results

Percent Breakup

The average percent breakup for all nine

experimental conditions was calculated and the results

inserted into the CCD grid as a way to compare and

analyze the breakup trends for different bead strengths and

screw geometries to operating conditions. To determine

the percent breakup of the stress beads, the areas under the

RTD and RSD curves were calculated and used in the

following equation:

{eq1}

Where Ac is the area under the stress bead, or RSD, curve

and Ar is the area under the dye, or RTD, curve.

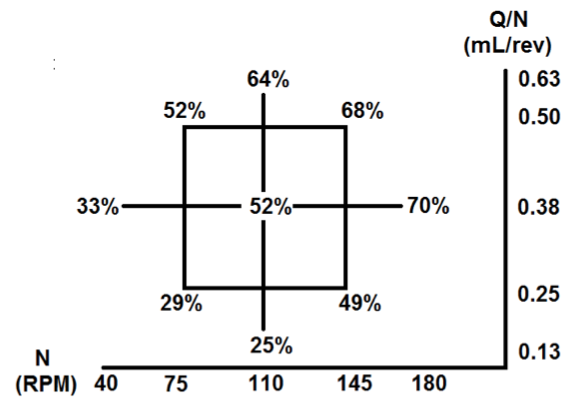

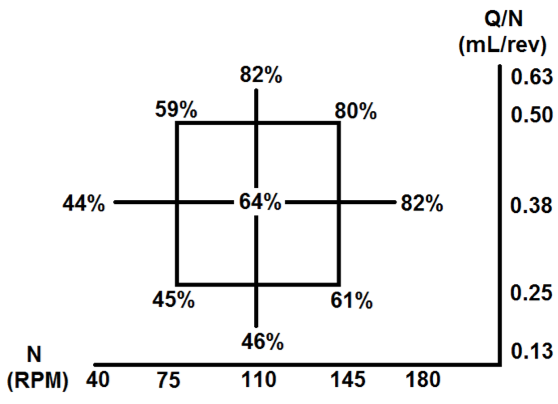

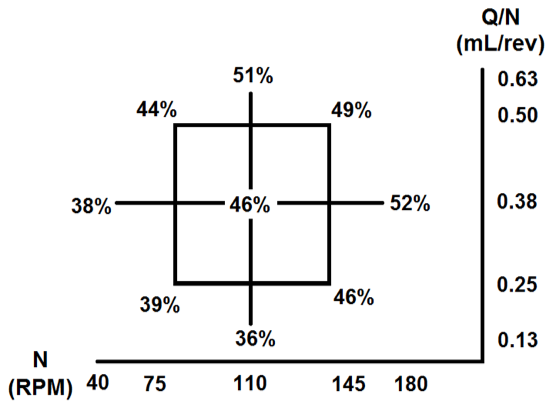

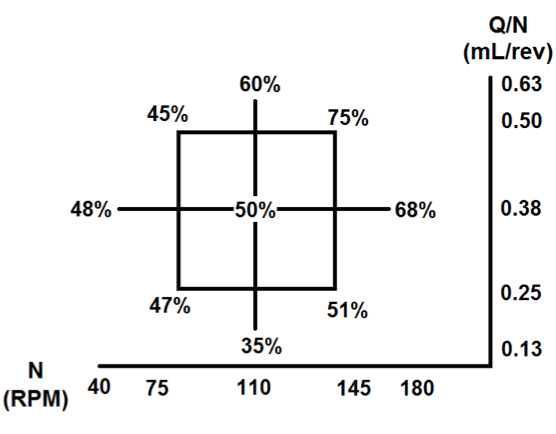

Three different strength stress beads were studied

for this research, 92 kPa, 119 kPa, and 158 kPa. Figures 4

through 9 present the percent breakup results for each bead

from lowest strength to highest using the CCD grid

display.

Figure 4. Percent breakup of 92 kPa beads using narrow kneading block

Figure 5. Percent breakup of 92 kPa beads using wide kneading block

Figure 6. Percent breakup of 119 kPa beads using narrow kneading block

Figure 7. Percent breakup of 119 kPa beads using wide kneading block

Figure 8. Percent breakup of 158 kPa beads using narrow kneading block

Figure 9. Percent breakup of 158 kPa beads using wide kneading block

For all different strength stress beads certain

patterns reappeared within the CCD grids. The wide KB

geometry for every operating condition had a higher

percent breakup than the narrow KB configuration.

Additionally, the average breakup between grids decreased

linearly with the strength of the stress bead, thus the lowest

breakup results were seen with the strongest bead, the 158

kPa bead. Also the diagonals from the upper right to the

lower left direction for all the grids, which approximately

have the same mass flow, showed similar percent

breakups. The diagonals from the lower left to the upper

right direction showed an increase in breakup, displaying

the significance of N and Q/N.

Each CCD grid was entered into JMP ® 9.0.0

statistical software for additional quantitative analysis. The

results of the statistical report were organized in Table 1.

The most notable result the statistical report indicated was

which operating parameters proved significant on a 95%

confidence interval. In all strength beads only two

parameters were found to be significant, N and Q/N. The

magnitude of the coefficients of N and Q/N are presented

in Table 1. The last third of Table 1 provides statistical

output for the concatenated wide and narrow geometry

grids, which contributed a factor of change between the

overall average and a specified screw configuration.

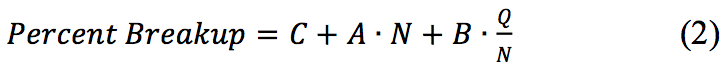

Equation 2 provides the general form of the

predictive equation obtained. The predictive equation

shows that percent breakup is only a function of screw

speed and specific throughput. Coefficient A specifies the

influence of screw speed on the breakup and coefficient B

specifies the influence of specific throughput on the

breakup. The constant C represents the average breakup for

a specific grid or the intercept. The coefficients are also

displayed in Table 1.

Table 1. Percent Breakup Predictive Equation Coefficients

The kneading block rows labeled “Combined”

represents the average values of the narrow and wide KB

equations. The “[Narrow]” column represents the percent

shift required to bring the average breakup down to the

breakup of the narrow KB grid. The negative sign indicates

that the narrow KB breakups were all less than the average

percent breakup.

Closer inspection of the comparison between

grids brought about additional observations. When

comparing the 92 and 119 kPa strength beads against each

other there is a clear decrease in breakup from the 92 kPa

to the 119 kPa beads. This result concludes that more of

the fluid experiences the lower critical stress level of 92

kPa. For the narrow KB configuration the percent breakup

increased by 10% when changing from the 119 kPa beads

to the 92 kPa beads. Similarly, for the wide KB

configuration the increase was 6%. An explanation for this,

is that for the wide KB there was already a higher percent

breakup, thus less of a chance for increase. Change in

configuration between the 158 and the 92 kPa beads

showed a similar difference. For the narrow KB there was

a difference of 12% and for wide KB a change of 10%.

Again the narrow KB showed more sensitivity to the

change in bead strength. However, between the 158 and

119 kPa beads the difference for the wide KB was 5%, but

the narrow KB only a 2% variation.

Examination of Table 1 yields a deeper

understanding into the causes of breakup and the stress

bead approach. The magnitude of the coefficients in Table

1 represent the sensitivity of the predictive equation to the

changes in input parameters (N, Q/N). The coefficients of

92 kPa beads, compared to the other two beads, has the

largest difference in magnitude between the N and Q/N

coefficients for each screw geometry, with Q/N always

playing a much greater role in percent breakup. The 119

kPa beads have the coefficients with the greatest

magnitude, with values of approximately 9 and 10 for both

N and Q/N for the wide and narrow KB configurations,

which are about double those for the other two stress

beads. This spike in magnitude for the 119 kPa beads

shows that they are the most sensitive with respect to operating conditions. The last observation from Table 1

comes from the 158 kPa bead data. Although the 92 kPa

beads have the largest difference between N and Q/N for

each respective screw configuration, the coefficients for

both N and Q/N for the 158 kPa beads nearly double when

moving from the narrow KB results to the wide KB results.

The other two bead strengths have approximately the same

magnitude for both types of mixing sections. This indicates

that the strongest bead, the 158 kPa, were most sensitive to

the geometry change.

Figure 6. RSD curves 2.4/75 for all three strength beads under a single RTD

Figure 6 above displays the visual representation

of the variation in bead strength with respect to stress

distribution. The selected operating condition was 2.4

lbs/hr and 75 RPM because the curves in this range are

mainly noise free. There are three RSD curves depicted,

one for each stress bead studied. The RSD curve with the

highest magnitude is the 92 kPa bead due to its low critical

stress level. The 119 and 158 kPa beads follow in that

order. This agrees with the quantitative results seen in the

CCD grids. The delay times of all three RSD curves also

exhibits an interesting trend. As the bead strength increases

the delay time becomes longer. This phenomenon is

attributed to more beads passing through unbroken. It has

been shown that the material that comes through the

fastest, travels through the center of the channel where the

stresses are the lowest [11]. The lower critical breaking

stress occurs closer to the center of the channel and will

have a shorter delay time. The higher critical breaking

stress will be experienced closer to the wall resulting in a

longer delay time.

Conclusions

A real time measuring technique for RSD has

been developed in an extruder, using a method involving

stress beads and an optical probe to measure their breakup.

Three separate strength stress beads were used to expand the findings of previous studies and to continue to validate

the methodology. Through a DOE approach, data was

analyzed by evaluating percent breakup as a function of

operating conditions. Screw speed, N, and specific

throughput, Q/N, were found to be significant in breaking

of the stress beads for all conditions tested. Two different

mixing sections of equal length were investigated in this

study. One with only narrow KB and the other with only

wide KB elements, both backed by a reverse element. All

three beads showed to be more susceptible to breaking

under the wide KB configuration. Furthermore, breakup

results showed that the average breakup varied linearly

with the strength of the bead, meaning as the bead strength

went up the overall breakup went down for every operating

condition. The compiled RSD curves also displayed other

patterns with respect to bead strength. As the critical stress

level of the bead increases the delay time also lengthens,

and the magnitude of breakup decreases with increasing

bead strength.

Results from the CCD grids and the table of

coefficients provided additional information to characterize

the stress history. The lowest strength bead, the 92 kPa,

showed the greatest difference between magnitudes of

coefficients for each respective geometry proving they

were affected by specific throughput more than the other

two beads relatively. The strongest critical stress bead, the

158 kPa, had an almost doubling of coefficient magnitude

when moving from the narrow to wide KB geometry,

making the 158 kPa bead the most vulnerable to a screw

configuration change. However, the most interesting of all

the results were with the 119 kPa coefficients. The

coefficients for the 119 kPa beads was far greater than the

both the other two beads. The high magnitudes indicate the

119 kPa beads are the most sensitive to operating

conditions, and thus provide the greatest controllability for

manufacturers. It is postulated that the average stress in the

channel and the critical stress of the 119 kPa are closely

matched. As one changes conditions one strongly changes

the amount of fluid that experience the critical stress. The

ability to categorize stress history in real time enables

manufacturers to better understand how flow path truly

affects their machine and ultimately their product. Future

work will continue to broaden the range of beads studied

along with a greater variation of screw geometry, material,

and operating conditions.

Acknowledgements

I would like to acknowledge all the

undergraduates that aided in running the experiments for

this paper. Beyond the co-authors help from Betel Sime,

Bunty Bhatia, Alexander Moses, and Hoyoung Khang was

invaluable. Additionally, the help of Jason Nixon and Joe

Martin on the MATLAB analysis code provided great

assistance. Also, Mark Wetzel for his counsel and help in

the direction of the experiment.

References

1. K. Kohlgruber, “Co-Rotating Twin-Screw Extruders,”

Hanser Gardner Publications Inc., Ohio, 22-275

(2008).

2. Kluter, R. Kline, L. et al. A Systems Analysis of Meal,

Ready-to-Eat (MRE) Packaging Materials, Report to

Strategic Environment Research and Development

Program, 2-4 (2002).

3. Y. Li, “Effect of addition of carbon nanofibers and

carbon nanotubes on properties of thermoplastic

biopolymers,” Polymer, vol. 52, 2310-2318 (2011).

4. P. J. Cullen, Food Mixing: Principles and

Applications. John Wiley and Sons, (2009).

5. G. C. Papanicolaou, A. F. Koutsomitopoulou, and A.

Sfakianakis, “Effect of thermal fatigue on the

mechanical properties of epoxy matrix composites

reinforced with olive pits powder,” Journal of Applied

Polymer Science, vol. 124, 67-76 (2012).

6. L. Erwin, “New fundamental considerations on mixing

in laminar flow,” SPE-ANTEC Tech. Papers, vol. 24,

488 (1978).

7. M. Wetzel, C. Shih, and U. Sundararaj,

“Determination of Residence Time Distribution

During Twin Screw Extrusion of Model Fluids,” SPEANTEC

Tech. Papers, No. 827 (1997).

8. J. Curry and A. Kiani, “Measurement of Stress Level

in Continuous Melt Compounders,” SPE-ANTEC

Tech. Papers, vol. 36, 1599-1602 (1990).

9. D. Bigio, W. Pappas, H. Brown II, B. Debebe and W.

Dunham, “Residence stress distributions in a twin

screw extruder”, SPE ANTEC Tech. Papers, 1382-

1386, (2011).

10. D. Bigio, W. Pappas, H. Brown II, G. Fukuda, and R.

Adnew, “Variable strength stress bead analysis in a

twin screw extruder,” SPE ANTEC Tech. Papers,

(2012).

11. W. Pappas, G. Fukuda, H. Brown II, and D. Bigio,

Characterization and Comparison of Stress History in

a Twin-Screw Extruder Using Residence Stress

Distributions, Polymer Engineering and Science,

(2012).

Return to

Paper of the Month.